Vacuum Systems & Instruments

At UltraHighVacuum.com, we are proud to offer an extensive range of UHV systems designed to meet the precise demands of advanced research and industrial applications. Our systems are categorised into three main areas:

Physical Vapour Deposition (PVD), delivering high-purity thin film & nanoparticle coatings for cutting-edge materials development

UHV Controlled Environment Transport Systems, ensuring pristine sample handling and transfer without contamination

Plasma-Enhanced Chemical Vapour Deposition (PECVD), providing superior film uniformity and efficiency for complex coatings

Each system is precision engineered to deliver reliability, performance, and innovation, empowering our customers to achieve breakthrough results.

Featured Products

NL50 Benchtop Nanoparticle System

Low cost, one-touch benchtop nanoparticle system.

- Generate pure metallic or compound nanoparticles, including oxides and nitrides

- Deposit hydrocarbon-free, non-agglomerated nanoparticles

- Wide material selection: Au, Ni, Ir, Pt, and more

- Real-time deposition control via QCM

- Typical cycle time: 30 minutes

- Room temperature deposition, ideal for delicate substrates like graphene and Nafion

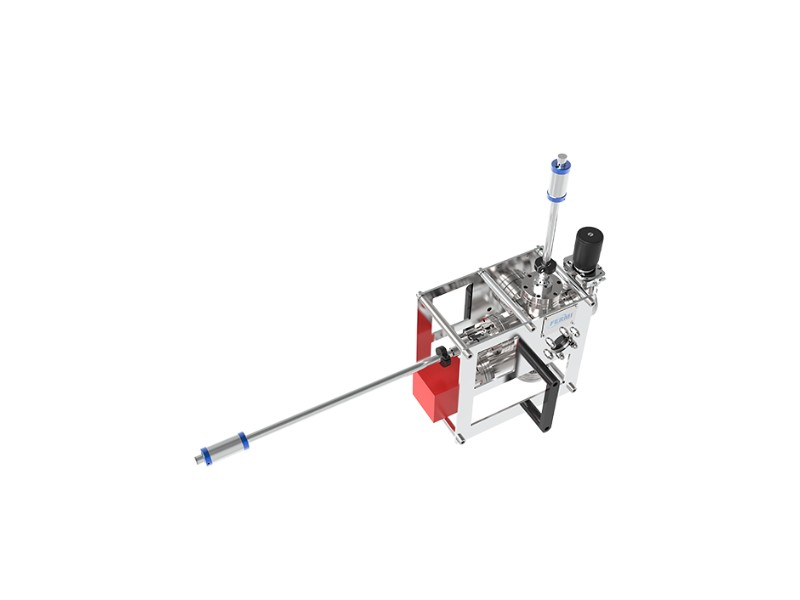

Portable UHV Suitcase

Developed to conveniently and safely transport samples in a UHV environment. The system is leak tested and baked to UHV standard before shipping, so it is ready to use out-of-the-box.

- Compact design reduces total weight while retaining complete functionality.

- Connects to other systems via a VAT NW40CF Manual Gate Valve and transfers sample holders via a magnetic transfer arm.

- Monitor samples even when in transit

- The provided pump (Ion/NEG) keeps the inner volume constant in UHV environment even at the shortage of power, so is an ideal tool for carrying sensitive samples for remote instruments.

- Base pressure is below <1 x 10-10 mbar for 48 hours after complete bakeout.

Small Scale Plasma-Enhanced Chemical Vapor Deposition System

This system is used to deposit layers under high vacuum conditions on samples that are RF biased . It is a low temperature technique when compared to typical CVD process, which is a major advantage.

- Base Pressure 1. 10 -6 mbar

- Samples up to 300 mm

- Inferior plate of 500 mm diameter with RF bias

- Various Process gases (TMS, Hexane, CF4, O 2, Ar)

- Pumping group (Suitable for corrosive gases)

- Automated Control

Case Studies

Take a look at different UHV Systems in collaboration with Vinci Technologies

Get in touch with us today to find out how we can support your UHV system requirements

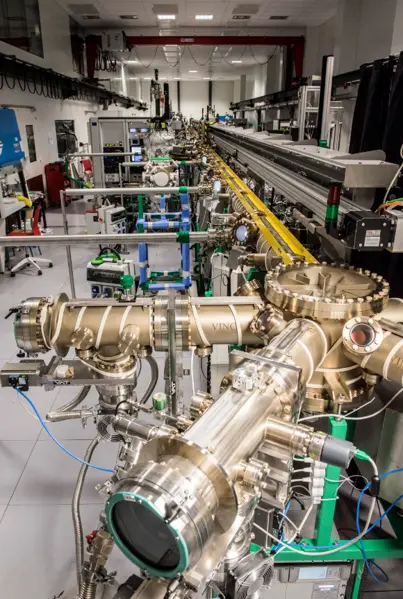

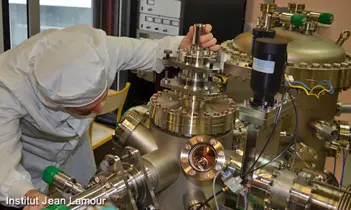

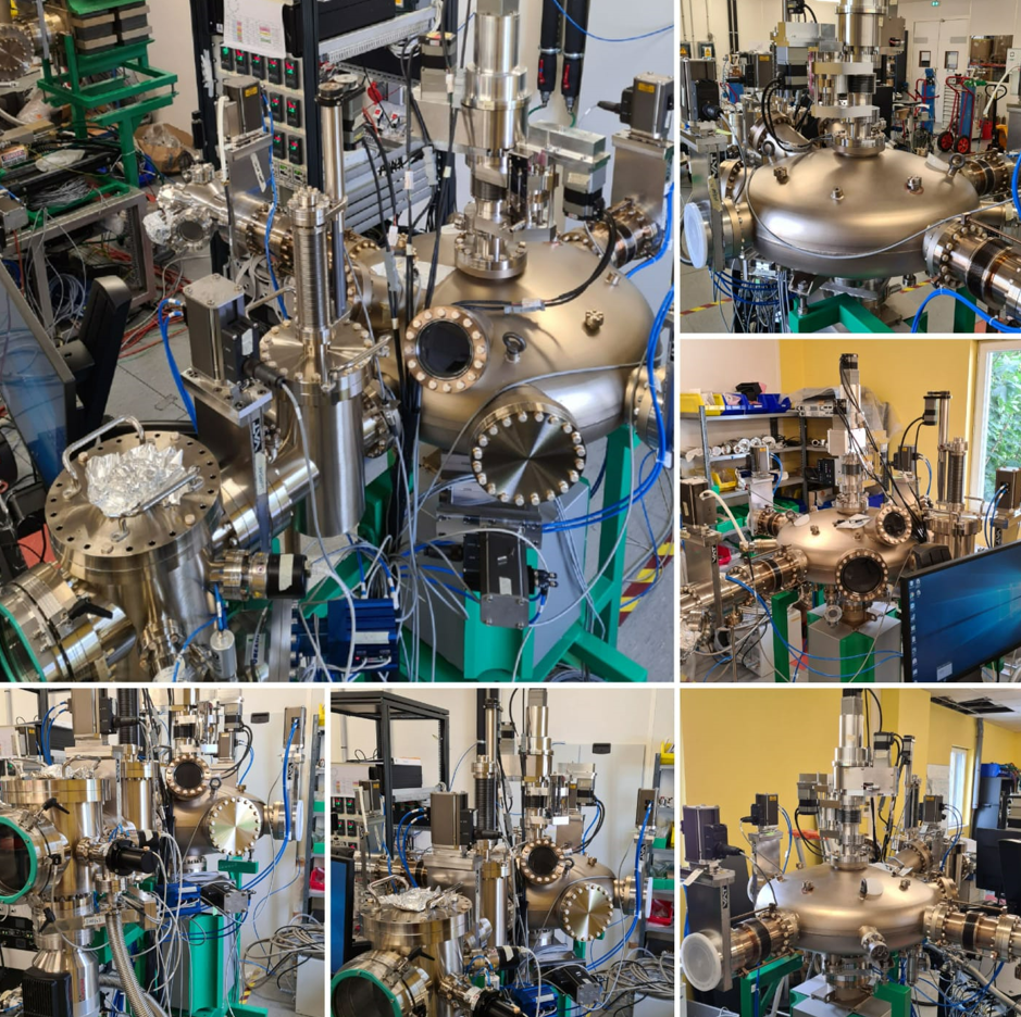

IJL, France - Daum Lab

The technical platform consists in 28 ultra-high vacuum systems, interconnected by the 70-meter long ultra-high vacuum transfer tunnel, including a 30-meter section dedicated to technology transfer. It combines multi-material growth techniques with multi-dimensional analysis techniques for thin films.

The research topics currently developed on the platform cover the following areas:

- Materials for spintronic: ferromagnetic, magnetic oxides, strong spin orbit coupling, topological effect, etc.

- Nanomaterials for optoelectronics, photovoltaics, etc.

- 2D materials: molecular, ultra-thin oxides, etc.

- Complex alloys and quasi crystals

- Functional materials: ternary oxides, Heusler alloys, etc.

Check out the following videos:

Virtual platform

Equipment for developing thin layers:

- 1 reactive Evaporation chamber : from Vinci Technologies

- 6 Sputtering: 4 from Vinci Technologies

- 6 Molecular Beam Epitaxy MBE: 3 from Vinci Technologies

- 1 Atomic Layer Deposition ALD: Intro Chamber by Vinci Technologies

- 1 Pulsed Laser Deposition PLD: from Vinci Technologies

- 1 Rapid Thermal Annealing RTA chamber: from Vinci Technologies

At each stage of their growth, these hybrid materials can be studied and characterized, while staying under ultra-high vacuum, by using different surface analysis techniques:

Equipment for surface analysis

- Chemical: Spectroscopies (XPS, Auger, ARPES)

- Physical: Magneto-optical Kerr effect; Spectroscopies; Photo- and Cathode-luminescence

- Structural: Electron diffraction (RHEED, LEED); Microscopies (STM, AFM, SEM)

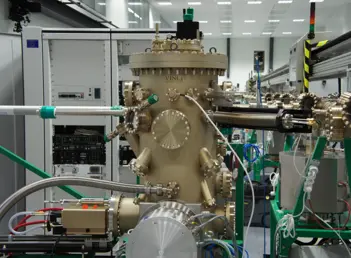

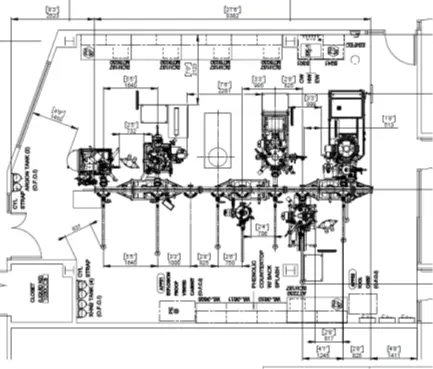

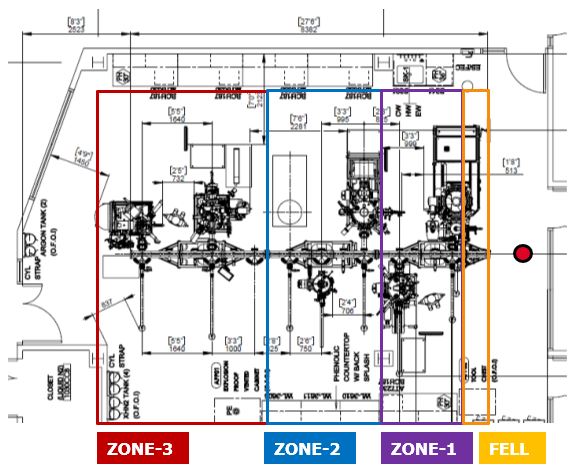

NYU, USA - CQP Lab

LAB BY ZONE

- UHV Transport system: Vinci Technologies Linear Transfer Tunnel (Mecatrans) version for samples of 2’’

- Zone-1/ Fast Entry load lock with chariot for up to 12 samples/substrates

- Zone-2/ PVD top view, Vinci Technologies growth system for metal contacts lower view

- Zone-3/ Vinci Technologies MBE-2D epitaxial gowth system top view, Vinci Technologies Preparation system for rapid thermal annealing lower view

- Zone-4/ Vinci Technologies Pulsed Laser Deposition epitaxial gowth system top view, Scienta Omicron ARPES analysis system lower view

Weizmann Inst. of Science, Israel - Condensed Matter Physics Lab

Equipment for developing 2D materials:

- 14m UHV Transport system: Vinci Technologies Linear Transfer Tunnel (Mecatrans) version for samples of 3’’

- 1 Glove Box MBRAUN

- 2 Sputtering: 1 from Vinci Technologies

- Plasmatherm ICP: coupled via Vinci Technologies buffer chambers

- UHV Thermal & Ebeam Evaporation from Vinci Technologies

- Atomic Layer Deposition ALD

- 1 redistribution chamber from Vinci Technologies

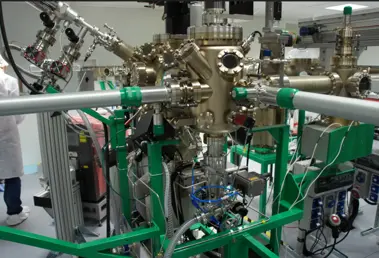

Naval Lab, USA - Cluster System

Equipment for developing 2D materials:

- Central Distribution Chamber with motorized automated transfer of 3 or 4’’ samples : Vinci Technologies CDC

- UHV 8 Cathode Sputtering system: from Vinci Technologies

- Specs Gmbh XPS

- UHV Molecular Beam Epitaxy MBE-2D from Vinci Technologies

- Future extension to STM

Get In Touch Today

Get in touch today to discuss your requirements, please contact us on

+44 (0) 1424 447726 [email protected]

Express delivery for the UK & Europe

Excellent customer care guaranteed

ISO 9001 approved company

Highest quality & performance assured