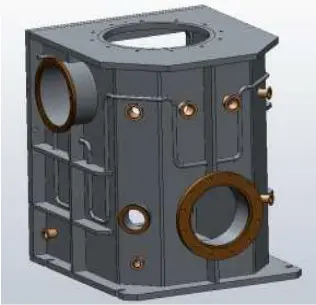

PVD-20

PVD20-S

The PVD20-S is a physical vapor deposition system, dedicated to the sputtering deposition process of materials. Its evolutionary design is particularly adapted to laboratory requirements in terms of every day applications, as is, its simplicity to use and its competitive price.

Specifications

| Thickness Homogeneity (@ working distance of approx. 500 mm) | +/-5% |

| Thickness Reading Precision | 0.1 A |

| Deposition Rate Reading Precision | 0.01 A |

| Vacuum Base Pressure | 10-7 mbar |

| Pump group | TMP (cryo for 10-8 mbar range) |

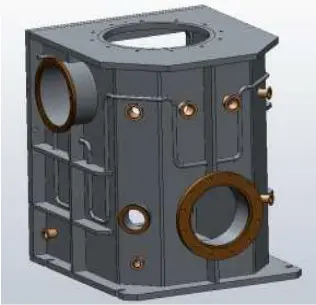

Core System Features

- D-shape steel – 500 mm diameter cylindrical

- Full access frontal Door with 2 viewports for easy

maintenance - Sample holder for substrates up to 6” in diameter

- Rotating and heating (up to 350°C) substrate holder

- Water cooling to avoid excess heating

- Secured cryo pumping group (option)

- Loadlock (option)

- RF plasma pre-cleaning (option)

Sputtering Process

- Up to 4 x 3-inch cathode magnetrons in Sputter Up configuration

- RF / DC power supply

- Process pressure : 10-3 – 10-1 mbar with a motorized throttle valve

- Up to 8 cathodes in sputter up configuration

- Gas panel for Ar, O2, N2

- Accurate control of deposition rates (crystal sensor)

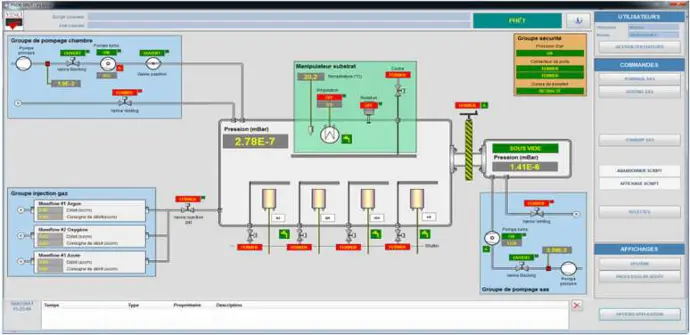

Easy to Use Software

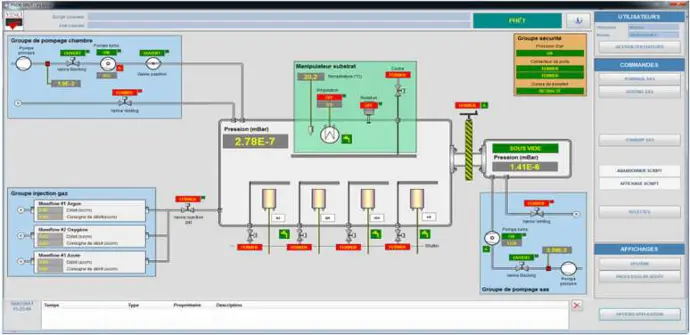

The R&D orientated system can be supplied with an easy to use automation software for full control of any deposition process.

Process supervision software with:

- Vacuum Display

- Process Pressure display

- Pressure display

- Temperature control

- Valve/Shutter management

Fully & Semi Automatic modes

Recipe modes with traceability

User mode Access Levels

Safety management through a PLC:

- Interlock management for power supplies

- Automatic switching of the machine in safe mode

- Pressure, actuators and valves management

- First level securities management

Hardware :

Integrated PC with windows 7 connected to a PLC

Compatibility Matrix

| Configuration type | |

|---|---|

| PVD20-S | |

| SUBSTRATE HEATING (up to 400°C or 900°C) | ✓ |

| SUBSTRATE ROTATION | ✓ |

| PULLEY FOR QUICK CHANGE OF DEPOSITION STAGE | ✓ |

| CATHODES 3″ | Up to 4 |

| RF POWER SUPPLY | ✓ |

| DC POWER SUPPLY | ✓ |

| LOAD LOCK | ✓ |

| RF PRE-CLEANING | ✓ |

| QUARTZ CONTROLLER | ✓ |

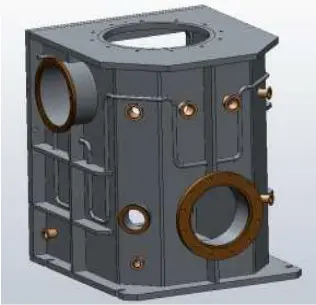

PVD20-TE

The PVD20-TE is a physical vapor deposition system, dedicated to the joule heating deposition process of materials. Its evolutionary design is particularly adapted to laboratory requirements in terms of every day applications, as is, its simplicity to use and its competitive price.

Specifications

| Thickness Homogeneity (@ working distance of approx. 500 mm) | Better than +/-5% |

| Thickness Reading Precision | 0.1 A |

| Deposition Rate Reading Precision | 0.01 A |

| Vacuum Base Pressure | 10-7 mbar |

| Pump group | TMP (cryo for 10-8 mbar range) |

Core System Features

- D-shape steel – 500 mm diameter cylindrical

- Full access frontal Door with 2 viewports for easy

maintenance - Sample holder for substrates up to 6” in diameter

- Rotating and heating (up to 350°C) substrate holder

- Water cooling to avoid excess heating

- Secured cryo pumping group (option)

- Loadlock (option)

- RF plasma pre-cleaning (option)

Thermal Evaporation Process

- Evaporation by joule effect

- Up to 4 sources (boats, rods, baskets, filament, crucibles)

- Cross contamination shields included

- DC power supply with temperature regulation

- End Hall Effect pre clean/deposition assist

- Gas panel for Ar, O2, N2

- Accurate control of deposition rates (crystal sensor)

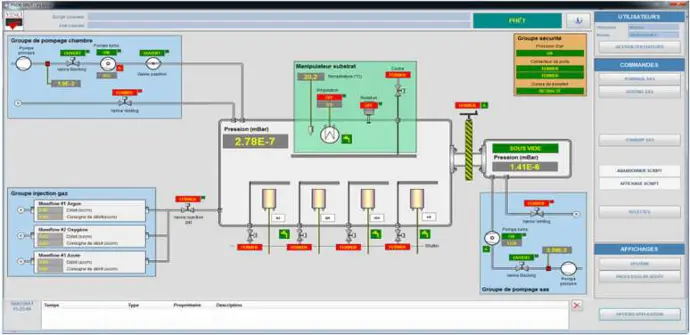

Easy to Use Software

The R&D orientated system can be supplied with an easy to use automation software for full control of any deposition process.

Process supervision software with:

- Vacuum Display

- Process Pressure display

- Pressure display

- Temperature control

- Valve/Shutter management

Fully & Semi Automatic modes

Recipe modes with traceability

User mode Access Levels

Safety management through a PLC:

- Interlock management for power supplies

- Automatic switching of the machine in safe mode

- Pressure, actuators and valves management

- First level securities management

Hardware :

Integrated PC with windows 7 connected to a PLC

Compatibility Matrix

| Configuration type | |

|---|---|

| PVD20-TE | |

| SUBSTRATE HEATING (up to 400°C or 900°C) | X |

| SUBSTRATE ROTATION | X |

| PULLEY FOR QUICK CHANGE OF DEPOSITION STAGE | X |

| JOULE HEATERS | Up to 4 |

| RF POWER SUPPLY | X |

| DC POWER SUPPLY | X |

| LOAD LOCK | X |

| RF PRE-CLEANING OR DC ION BEAM | X |

| QUARTZ CONTROLLER | X |

PVD20-EB

The PVD20-EB is a physical vapor deposition system, dedicated to the electron beam deposition process of materials. Its evolutionary design is particularly adapted to laboratory requirements in terms of every day applications, as its simplicity to use and its competitive price.

Specifications

| Thickness Homogeneity (@ working distance of approx. 506 mm) | < +/-5% |

| Thickness Reading Precision | 0.1 A |

| Deposition Rate Reading Precision | 0.01 A |

| Vacuum Base Pressure | 10-8 mbar |

| Pumping group | Cryogenic |

Core System Features

- D-shape steel – 500 mm diameter cylindrical

- Full access frontal Door with 2 viewports for easy

maintenance - Sample holder for substrates up to 6” in diameter

- Rotating and water cooled substrate holder

- Water cooling to avoid excess heating

- Secured cryo pumping group

-

E-Beam Evaporation

- 8X8 cc or 6X7 cc electron beam source (Ti, Au, Ag, Al, Cr, W, Pt)

- Power supply from 3 kW to 12 kW

- Gas panel for Ar, O2, N2

- Accurate control of deposition rates

- Loadlock (option)

- RF plasma pre-cleaning (option)

-

Easy to Use Software

The R&D orientated system can be supplied with an easy to use automation software for full control of any deposition process.

Process supervision software with:

- Vacuum Display

- Process Pressure display

- Pressure display

- Temperature control

- Valve/Shutter management

Fully & Semi Automatic modes

Recipe modes with traceability

User mode Access Levels

Safety management through a PLC:

- Interlock management for power supplies

- Automatic switching of the machine in safe mode

- Pressure, actuators and valves management

- First level securities management

Hardware :

Integrated PC with windows 7 connected to a PLC

Compatibility Matrix

| Configuration type | |

|---|---|

| PVD20-EB | |

| SUBSTRATE COOLING (down to 150°C) | X |

| SUBSTRATE ROTATION | X |

| PULLEY FOR QUICK CHANGE OF DEPOSITION STAGE | X |

| CRUCIBLES | Up to 8 |

| CAPACITY/CRUCIBLE | Up to 15 cc |

| LOAD LOCK | X |

| RF PRE-CLEANING | X |

| QUARTZ CONTROLLER | X |