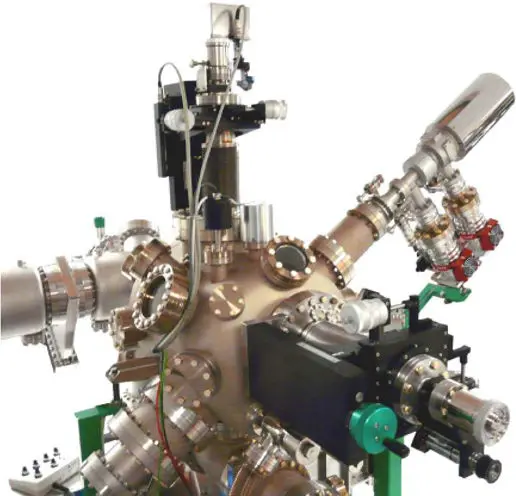

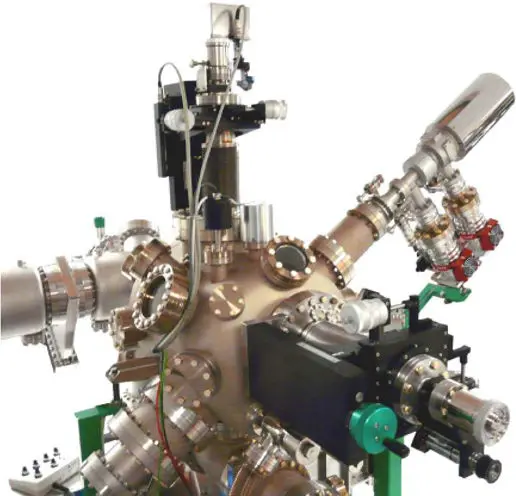

PLD 950

UHV Pulsed Laser Deposition System

Synthesis of complex materials & crystalline structures is an ever growing request from research & development. The Pulsed Laser Deposition (PLD) technique provides an intelligent solution for such requirements. It is a versatile coating technique that allows the growth of various materials such as nitrides, oxides, super lattices, polymers and composites etc.

With over 30 years experience in vacuum and UHV, Vinci Technologies provides tailored solutions to customer requirements with this laser-MBE system. This configuration adapts to a large field of growth parameters. For example, process pressure ranges from 10-10 to hundreds of mbar.

Flexible and evolving, this PLD equipment consists of a chamber with ports for process and characterization.

This system is compatible with 2-inch samples. The UHV & dry pumping design prevent the deposited films from contamination by external sources of pollution.

Samples can be transferred from load-lock chamber or from the UHV transfer tunnel the MECATRANS™.

Compatible with UHV transfer tunnel MecaTrans™, customer transfer modules or specific loading/unloading chambers.

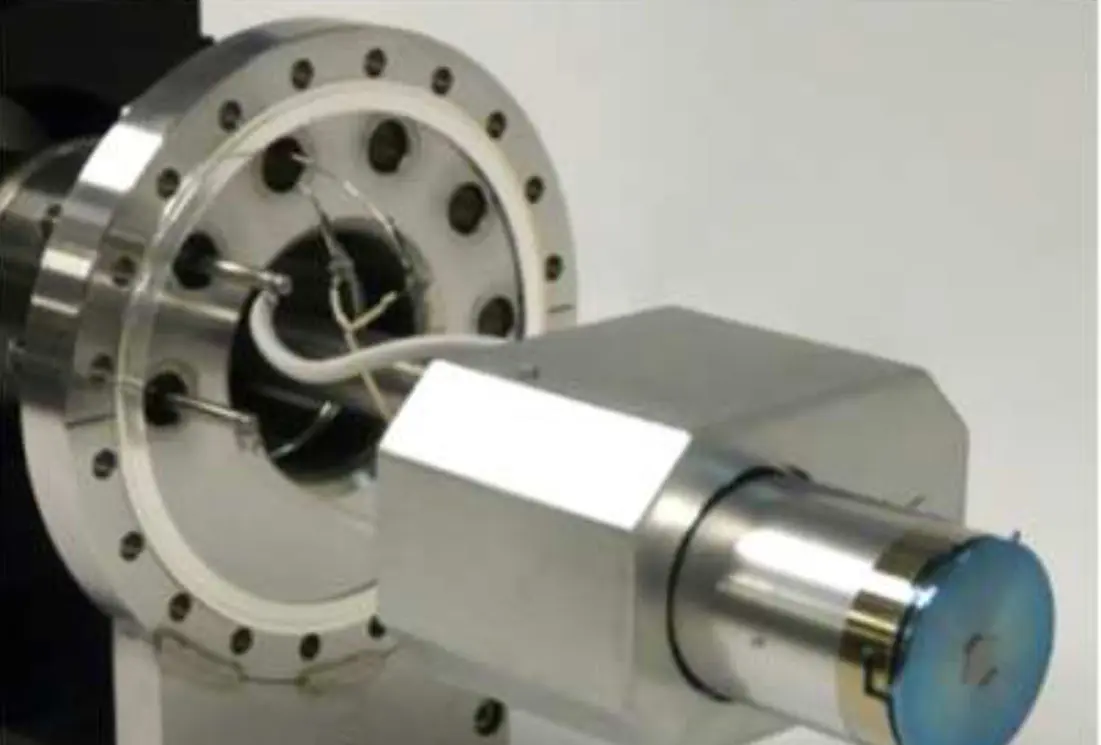

4-Target Holder Manipulator

- Up to 8 targets (option)

Consisting of XYZ stage on CF200 for positioning targets. Motorized Z-axis allows transfer on to the substrate manipulator. 0 to 60 rpm continuous rotation of the targets. Manual or motorized carrousel for sequential ablation.

High Pressure RHEED System

- 0.4 Torr O2 with 35kV

2 deflection units & 1 mechanical tilt. 2 differential pumping stages with isolation valves. Max oxygen pressure of 0.4 torr with 35kV electron source. Specific phosphorus screen with shutter.

Substrate Manipulator

- O2 compatible 950° Heater

- 2″ substrate

Consisting of XYZ table on CF150 for positioning sample holder and adjusting distance from target to substrate. Oxygen resistant heater is limited at a maximum temperature of 950°C. 0 to 60 rpm continuous rotation of the substrate. Manual or pneumatic integrated shutter following XYZ stage movements can be added.

Get In Touch Today

Get in touch today to discuss your requirements, please contact us on

+44 (0) 1424 447726 [email protected]

Express delivery for the UK & Europe

Excellent customer care guaranteed

ISO 9001 approved company

Highest quality & performance assured