UHV Linear Transfer Tunnel - Mecatrans

The ability to grow, control, manipulate and design materials from the atomic/nano-level via microstructure to macrostructure levels is a major driver both for fundamental research and applied technology in the Thin Films. The MECATRANS allows for the combination of deposition, analysis and post deposition treatment techniques, all connected under Ultra High Vacuum (UHV).

Various materials require different deposition processes in order to create multi-material devices. Therefore, as-deposited samples are easily transportable under a controlled environment with a base pressure of 1.10-10 Torr, which protects them from oxidation and other structural or chemical changes related to atmospheric exposure.

By combining several growth, deposition and analysis techniques, the MECATRANS permits the exploration of a large range of more complex and hybrid systems for materials control at the atomic scale.

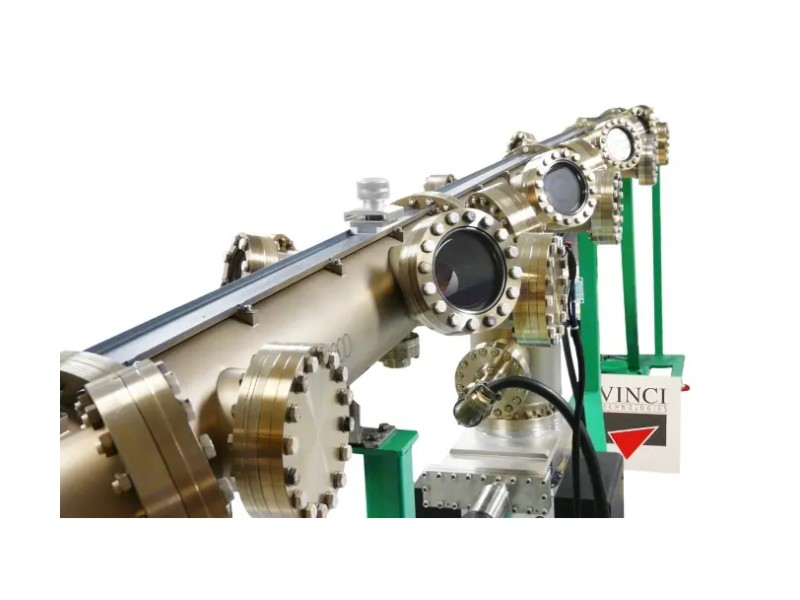

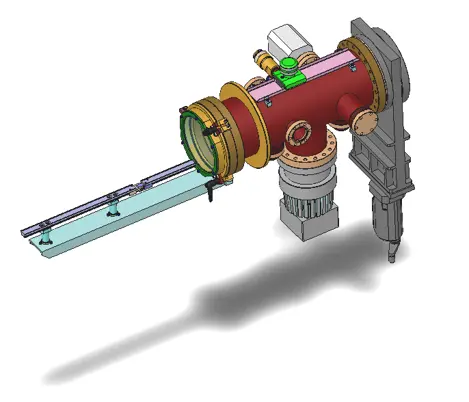

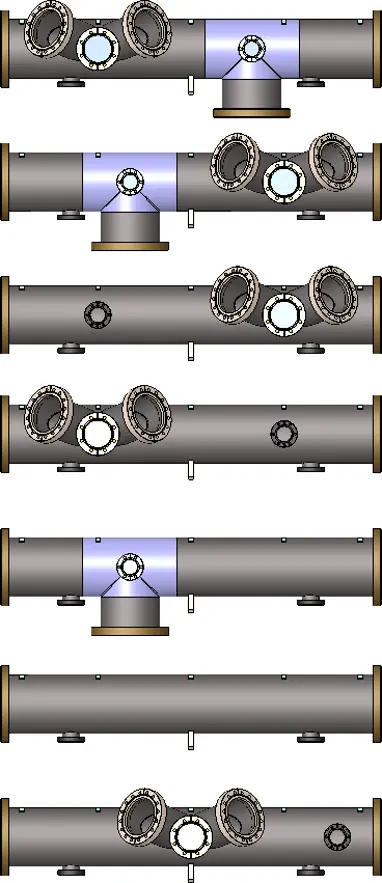

The MECATRANS is a stainless steel tunnel with an internal monorail upon which the substrate train is moveable.

The samples are transported through the UHV tube on this monorail train. By means of transfer rods, the samples can be exchanged between the train and the connected chambers. The MECATRANS accommodates for a 12 two-inch sample holder on the internal monorail.

To avoid any contamination between chambers and/or vibration conduction each UHV chamber is isolated by a UHV valve and features specific components.