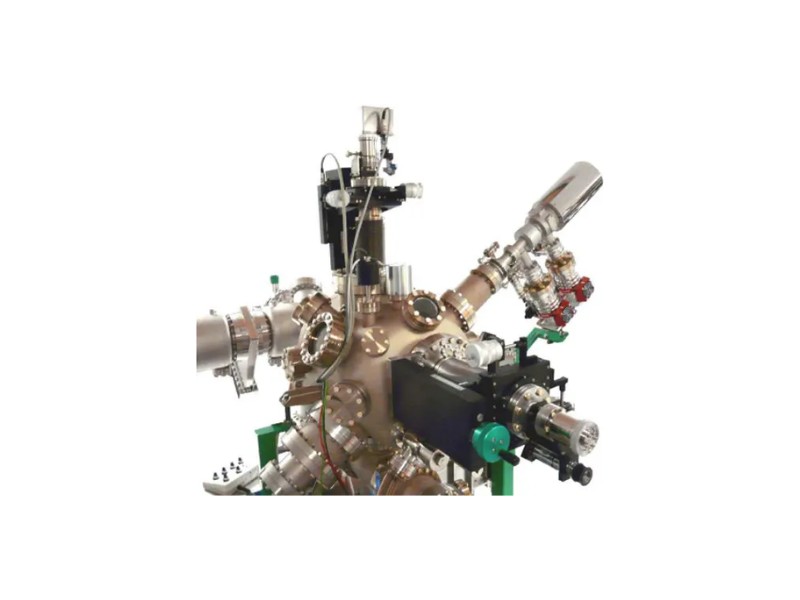

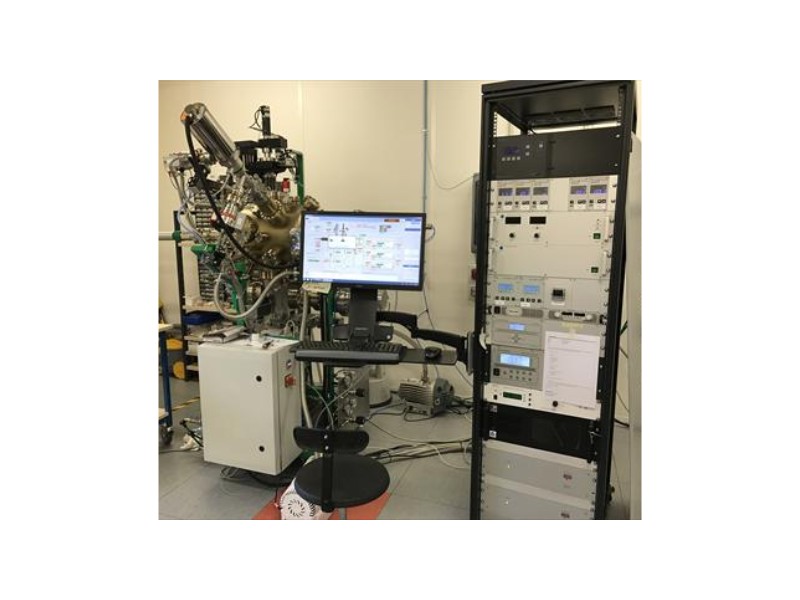

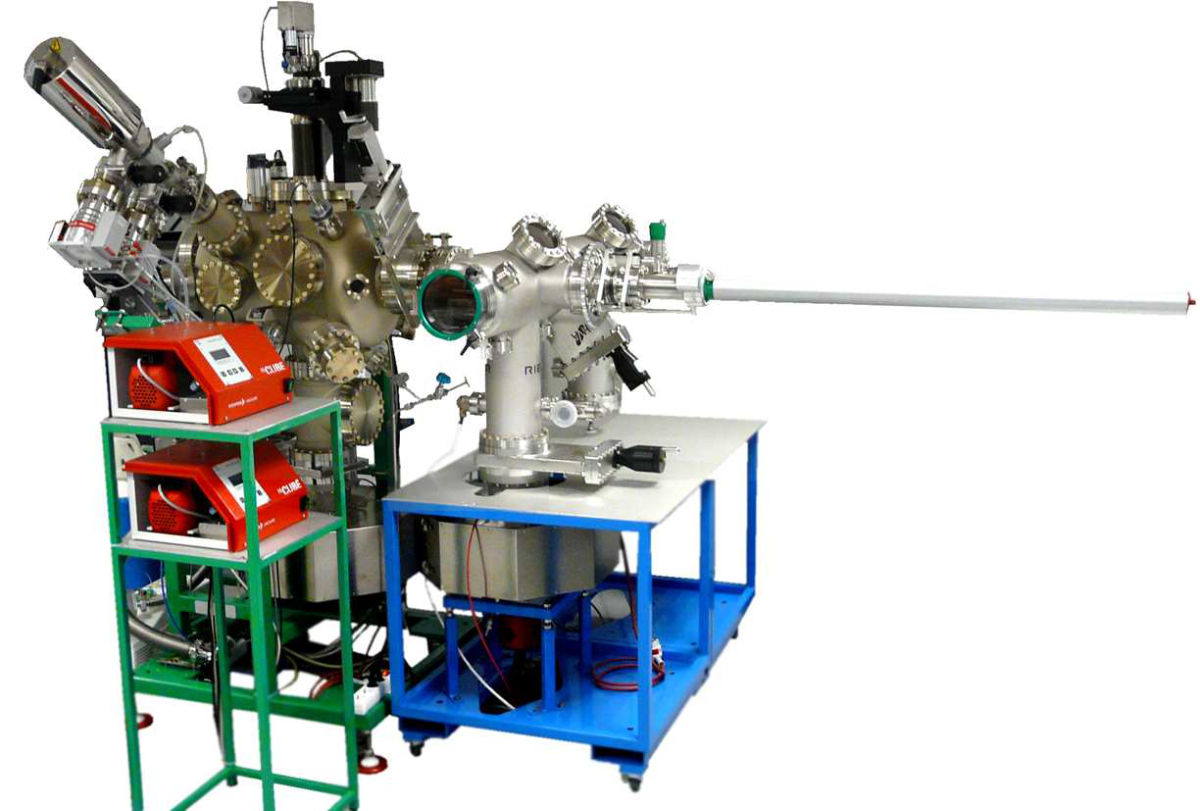

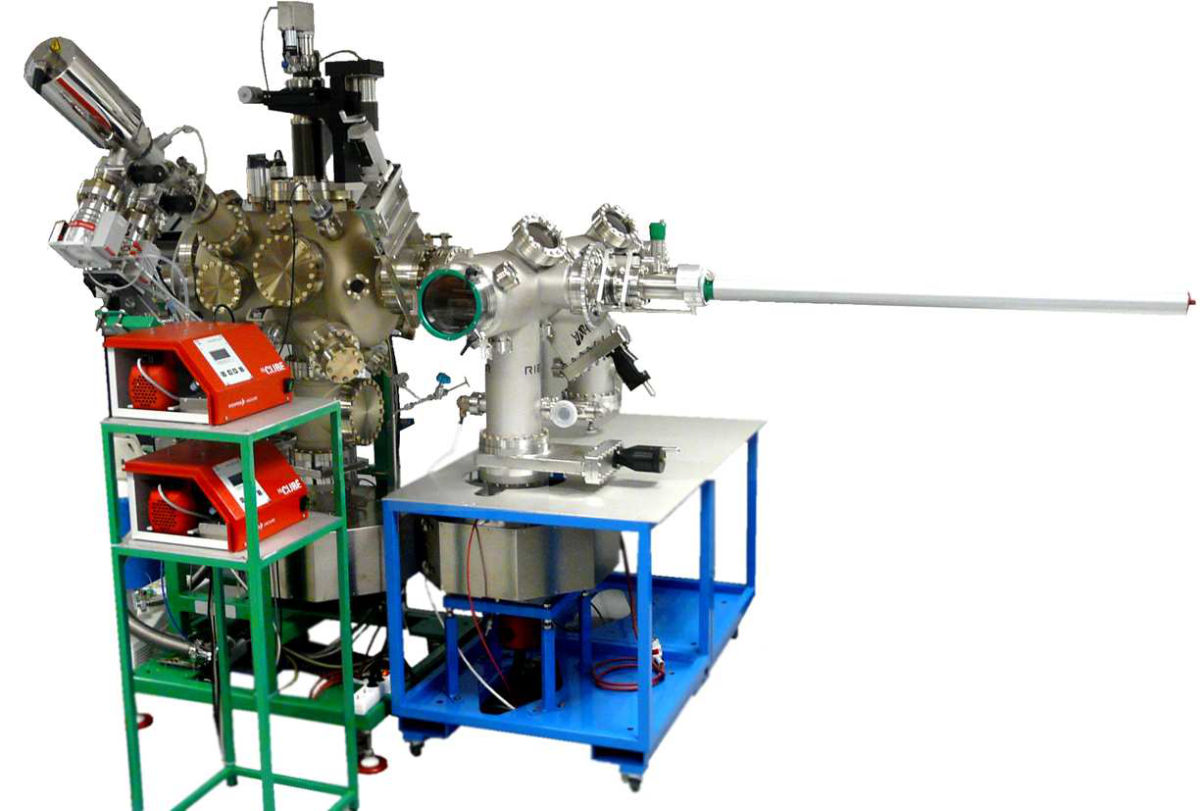

PLD 950 UHV Pulsed Laser Deposition System

Synthesis of complex materials & crystalline structures is an ever growing request from research & development. The Pulsed Laser Deposition (PLD) technique provides an intelligent solution for such requirements. It is a versatile coating technique that allows the growth of various materials such as nitrides, oxides, super lattices, polymers and composites etc.

With over 30 years experience in vacuum and UHV, Vinci Technologies provides tailored solutions to customer requirements with this laser-MBE system. This configuration adapts to a large field of growth parameters. For example, process pressure ranges from 10-10 to hundreds of mbar.

Flexible and evolving, this PLD equipment consists of a chamber with ports for process and characterization.

This system is compatible with 2-inch samples. The UHV & dry pumping design prevent the deposited films from contamination by external sources of pollution.

Samples can be transferred from a load-lock chamber or MECATRANS™ UHV transfer tunnel.

Applications:

• Thin film growth for stoichiometric films of complex compounds

Primary Features:

• Reactive or UHV Pulsed Laser Deposition capability

• RF plasma source

• 5-axis target holder (4 targets or 8 upon request)

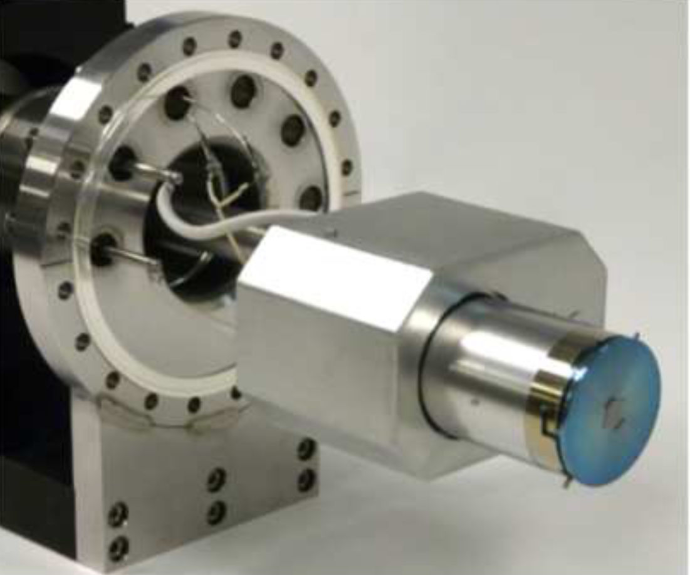

• Transferable 2-inch substrate and target holders

• Oxygen-resistant 950°C 2’’ sample holder

• 10-10 mbar chamber

• Turbo molecular, ion & titanium sublimation pumping

• Ports for in-situ characterization

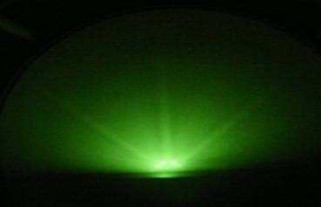

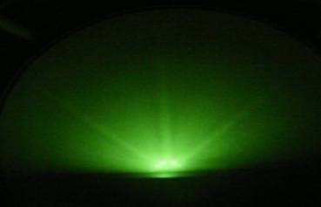

• High pressure RHEED

• Quick maintenance of laser window

• Load lock chamber

• Transfer tunnel compatibility

• Evolutionary system